Fuel Level Sensor Pdf

Fuel level sensor dut e can l 1000 mm can 2 0b interface measuring probe length 1000 mm.

Fuel level sensor pdf. Fuel level sensors features and benefits peace of mind monitor reefer fuel levels to prevent out of fuel shutdowns added protection and savings reefer s microprocessor continuously monitors diesel levels via fuel level sensor mounted in fuel tank alerts drivers when a low fuel situation can lead to. Upon customer request dut e sensors can be produced with any measuring probe length up. A float an actuating rod and a resistor. T ll14x fuel level sensor cut to length calibration instructions installation instructions e.

Applications tank level measurement and leak detection applications. Also the marine industry chooses the reed based level sensors for their fuel levels oil levels liquid propane gas 䱜 倀䜀尩 and bilge pump water detection and. It is commonly attached to the fuel pump and uses a float connected by a rod to a resistor in order to measure the fuel level. Issue the ssi ultrasonic fuel level sensor sends high frequency pulses then measures the echo in order to determine the fuel level in the tank.

Designers of level sensor requir ments generally select the hermetically sealed reed switch for their fault free sensing operations in the fuel tank oil levels對 etc. The fuel level sensor is the part of the fuel system that measures the amount of fuel remaining in your fuel tank. This combination of components sends a variable signal to the fuel gauge or an electronic device a little black box that actuates the fuel gauge. Rev 5 since the suitability of these products depends upon a wide range of factors not in our control fozmula limited expects and understands that you will conduct the testing and.

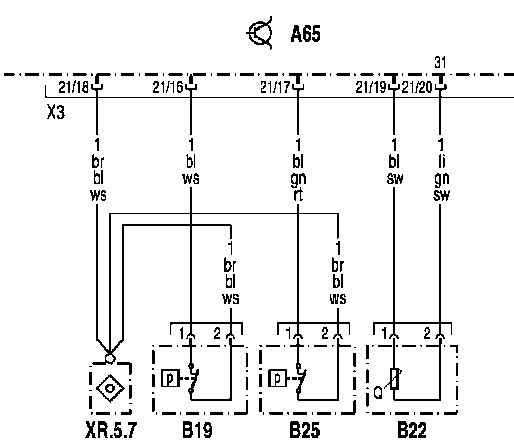

Corresponds to the external height of most common tanks. Fault codes for fuel level sensor. Additional fuel sensor or as a replacement of standard factory built in fuel level sensors see figure 3. Solution there are two attached files containing.

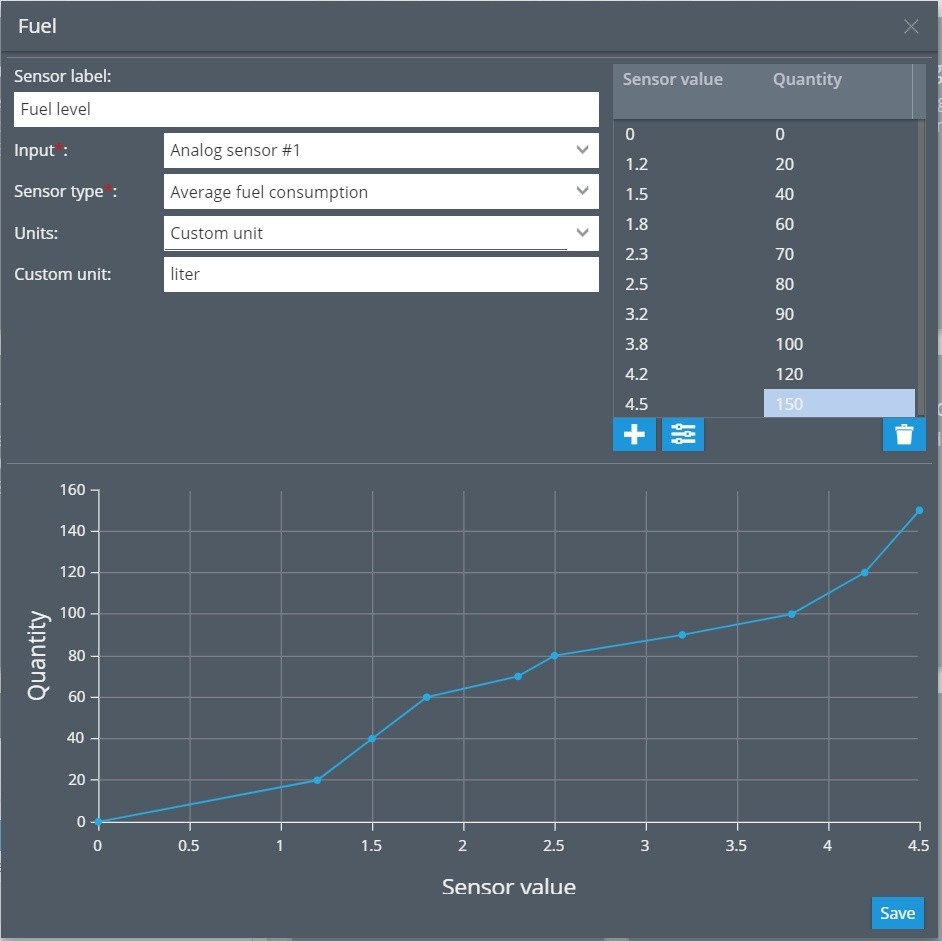

Using measurements from an additional probe in the sensor to compare filled fuel characteristics with the fuel used for calibration and calculate measurements accordingly this sensor sets a new industry standard and is twice as accurate as regular capacitive fuel level sensors. Figure 3 dut e application in vehicle monitoring and fuel consumption control system dut e is installed into a fuel tank of a vehicle. There are a range of technical terms used to describe this type of level. The sensor measures fuel level in the tank.

To test the resistance output of this ultrasonic sensor the sensor needs to be properly connected to power and ground. Pros compact no moving parts high pressure and temperature capability can detect tiny amounts of liquids cons invasive as the sensor requires contact with the liquid requires power certain thick substances can cause coating on the prism.