Fundamentals Of Sheet Metal Design

Unlike general purpose cad tools solid edge includes sheet metal specific features like emboss dimple drawn cut bead contour flange straight brake and etch.

Fundamentals of sheet metal design. Sheet metal fabrication is the process of forming parts from a metal sheet by punching cutting stamping and bending. To meet unique sheet metal design challenges like manufacturability solid edge streamlines the entire sheet metal product development process from cad design through flat pattern and drawing development. Inner radius or the bend radius of sheet metal should be. Sheet metal materials are the most commonly used materials in the structural design of communication products.

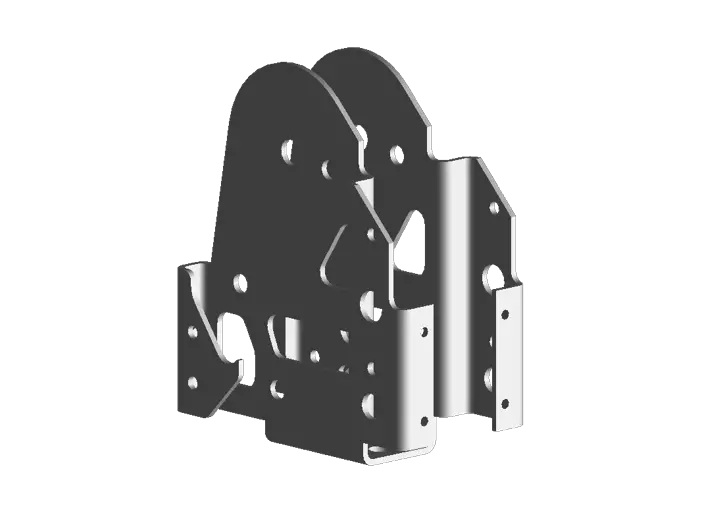

Bend relief refers to an indentation that designers should make on sheet metal designs so that the. We would like to show you a description here but the site won t allow us. Sheet metal is cut stamped punched sheared formed bent welded rolled riveted drilled tapped and machined. 3d cad files are converted into machine code which controls a machine to precisely cut and form the sheets into the final part.

Few thumb rules or sheet metal design fundamentals. The minimum hole diameter should be equal to or more than the sheet thickness. When a sheet metal design has small holes it requires smaller punches during operation. Distance from the bend to the hole edge should be equal to or more than twice the thickness of the sheet.

Selection principle of sheet metal materials. Hardware can be inserted into sheet metal components. The blackstone fundamentals of sheet metal design sheet metal design is key to the production of quality products. 5 basic factors in sheet metal design for manufacturability 1.

Sheet metal can be cut bent and stretched into an amazing array of shapes. While the design can guide you to speci c materials the materials themselves can often lead to functionality and cosmetic improvements based on performance characteristics of the chosen metal alloy. When designing with sheet metal there is a relationship between the design of the part the use of the part and the choice of material.