Fusion 360 Solid Into Sheet Metal

Our intention is to provide you a simple way to build your library by providing you with a handful of starter rules you can copy edit and save to your library.

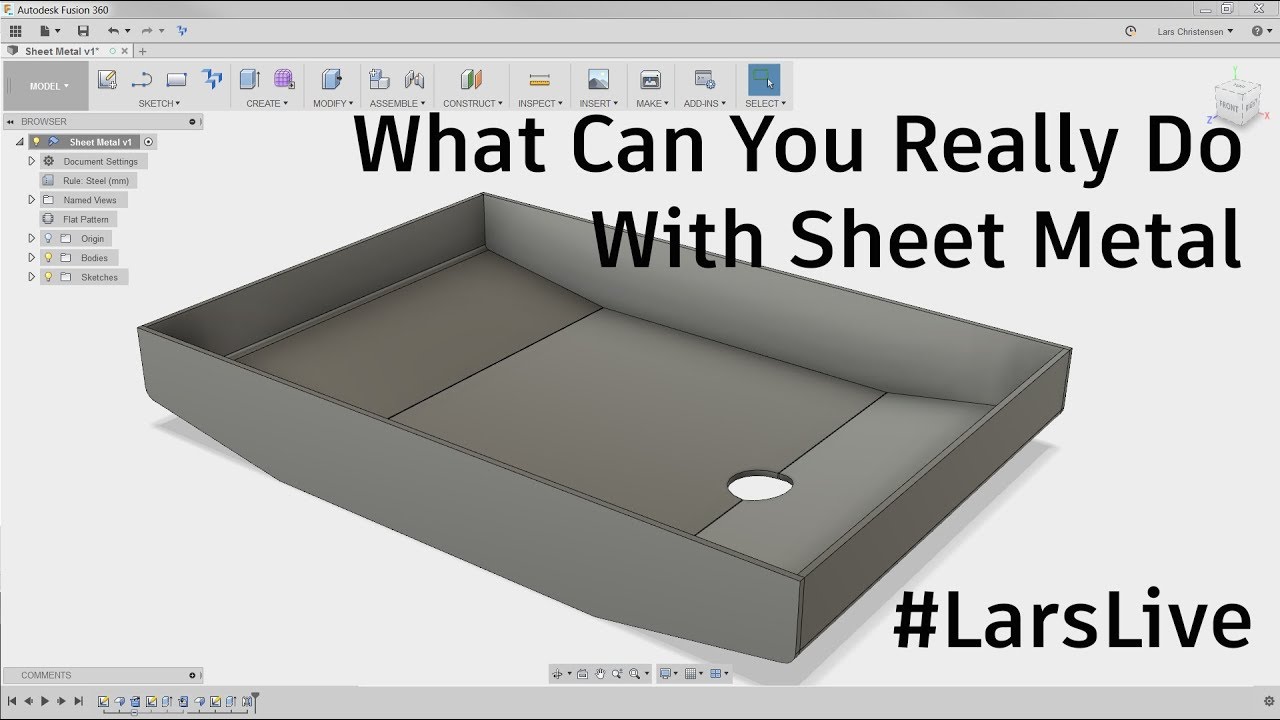

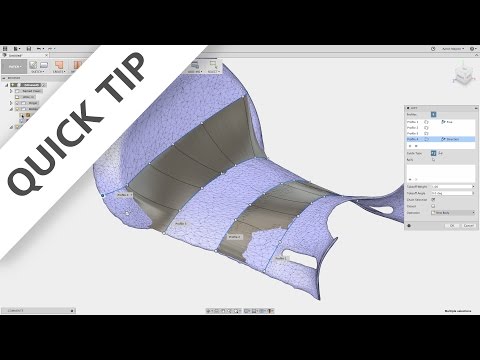

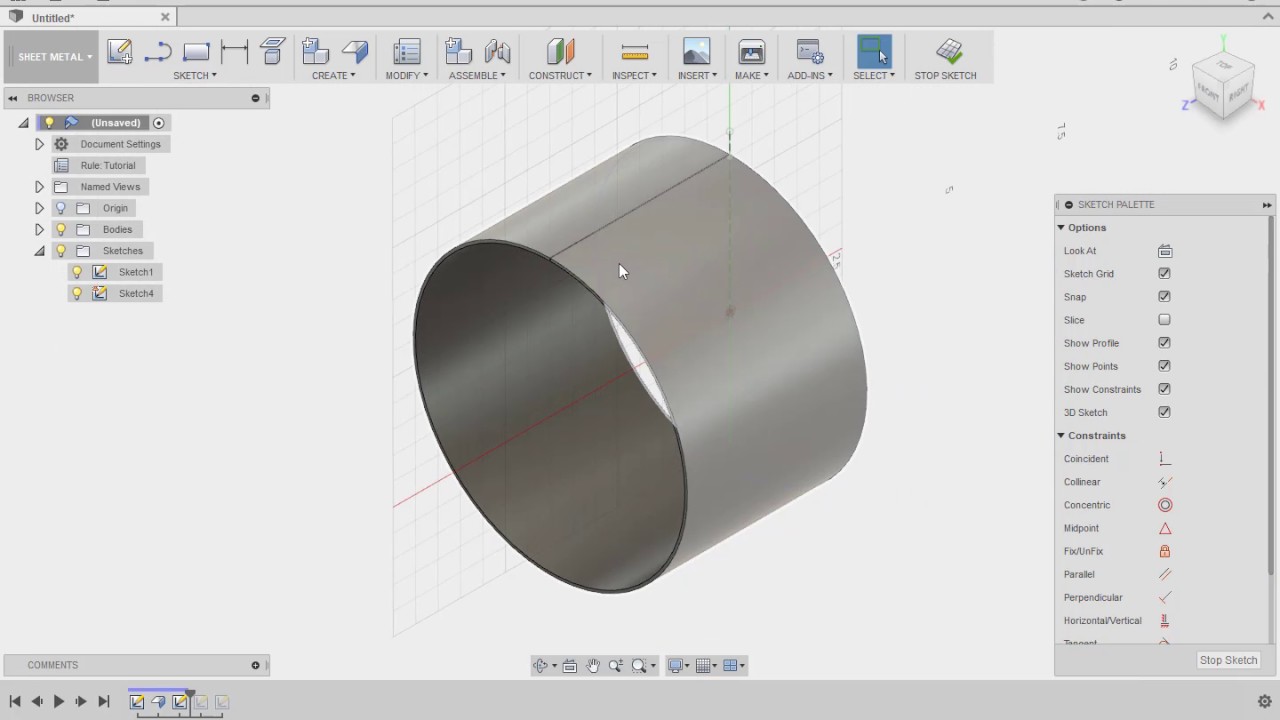

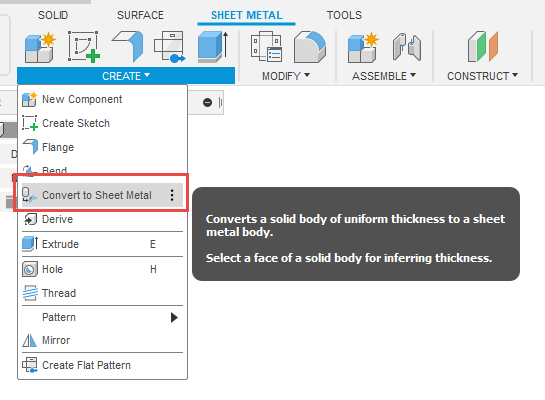

Fusion 360 solid into sheet metal. Fusion 360 has released the sheet metal modeling environment. When designing sheet metal assemblies it is often advantageous to create parts in the context of existing parts. Non native parts are imported into fusion 360 as solids or surfaces and need to be converted into sheet metal components before flattening. This quick tip covers a workflow of importing the model automatically applied rules sheet metal.

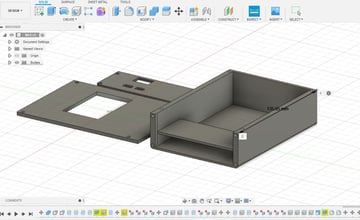

Fusion 360 is the only tool to integrate design to manufacture. Follow the steps to be able to create a flat pattern for the imported part. But fusion 360 doesn t just integrate the process from design to flat pattern. Here our intent is to turn this solid body into a sheet metal body.

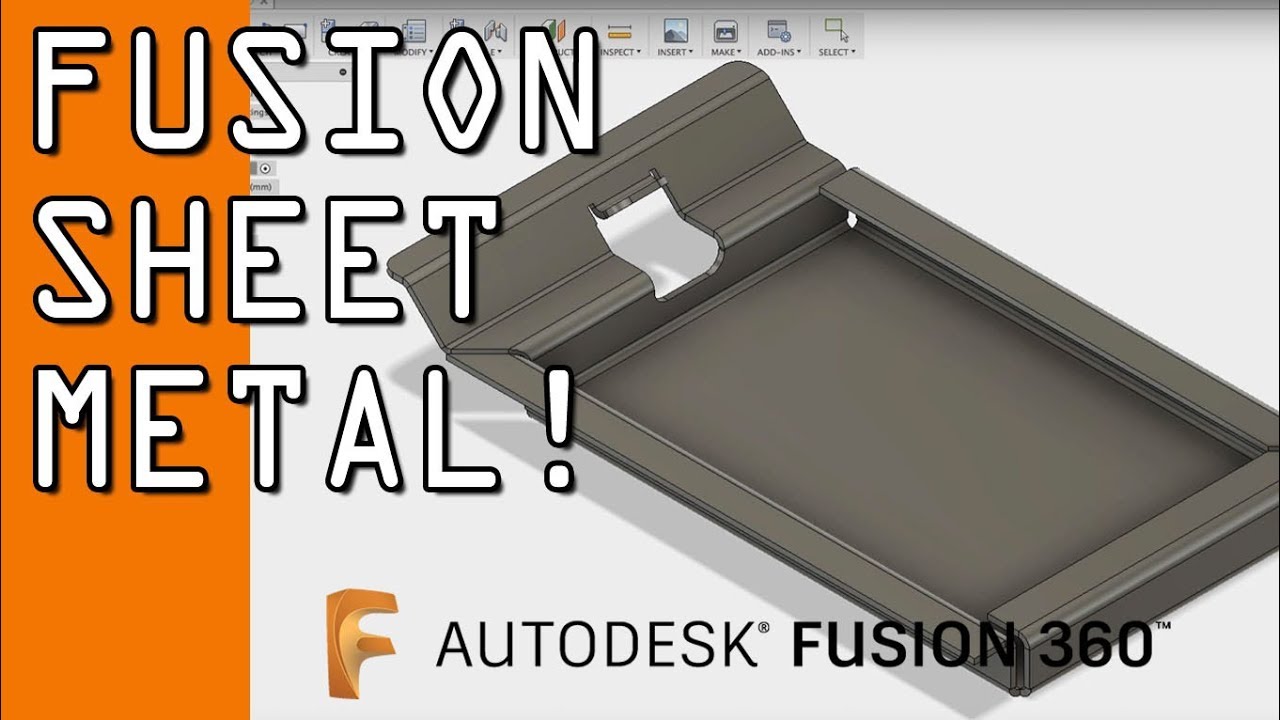

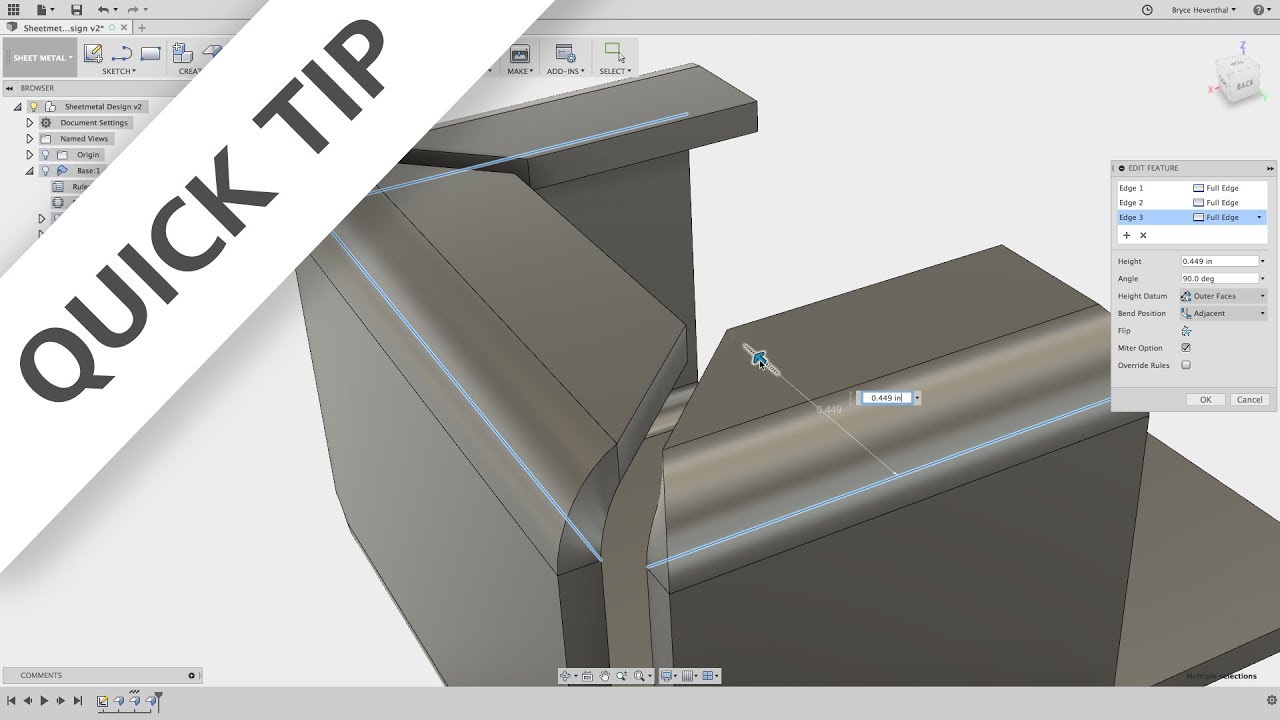

In fusion 360 we can merge these two bodies into one. Old user interface prior to august 2019 update. Basically just some 3mm aluminium with 90 degree bends on the end. Let s show how to create sheet metal bends folds flange unfold flat pattern and more.

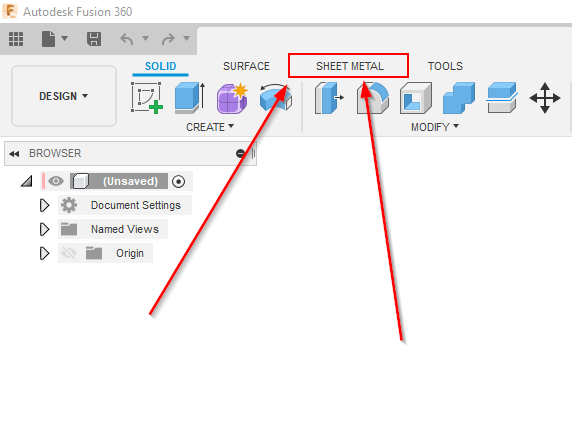

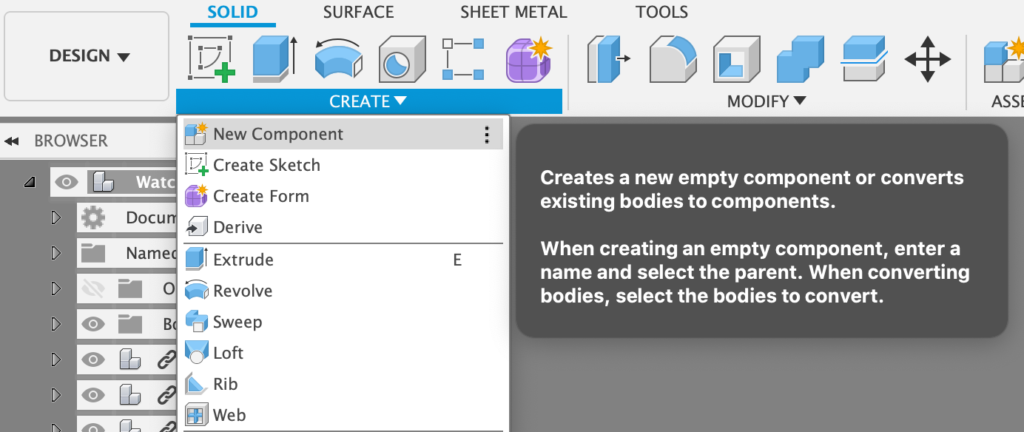

To do that we simply need to head to the solid tab head to modify and select combine. There is no option to access the sheet metal workspace in fusion 360 there is no option to access the sheet metal tab in the fusion 360 design toolbar. I ve drawn some brackets to hold members together. Traditional cad tools only take your sheet metal design from concept to dxf without integrating an expensive 3rd party add in.

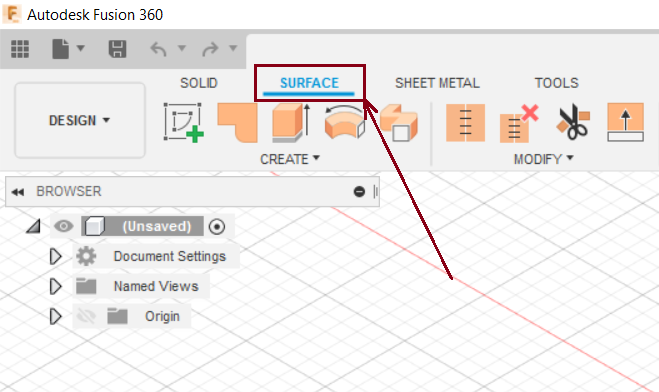

I want to get these laser cut and have to draw out a dxf for them. In the new ui the sheet metal environment is located in the tabs above the icons. Thickness bend radius k factor relief shapes etc. Creating sheet metal components in autodesk fusion 360.

The goal is to create an actual physical product. We re calling these sheet metal rules in fusion 360. Hi all i m designing a laser cutter and have drawn everything up in fusion 360. As you create your sheet metal parts within the same file you will want to make them components instead of bodies since assembly joints cannot be placed between bodies.