Galvannealed Steel Sheet Properties

Meets astm a653 09 specifications requirements.

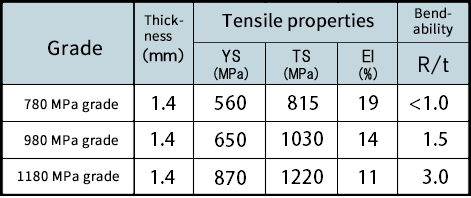

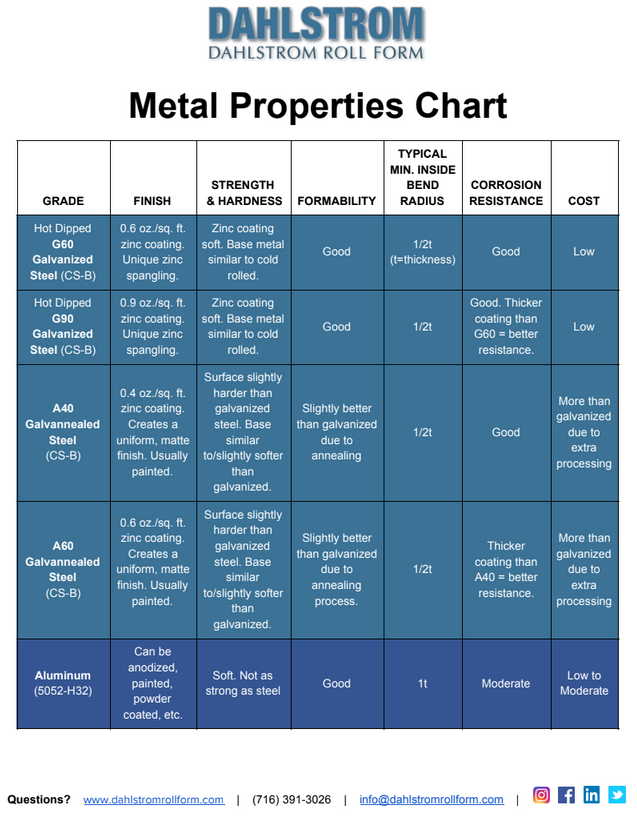

Galvannealed steel sheet properties. Class 1 mechanical properties chemical composition. Steel base guaranteed typical range guaranteed maximum percent longitudinal tensile carbon c 0 25 yield strength minimum ksi 80 80 117 phosphorus p 0 04 tensile strength minimum ksi 82 82 120. This allows for the galvannealed steel to be more ductile and flexible. At times the galvannealed coating may appear similar to uncoated cold rolled steel.

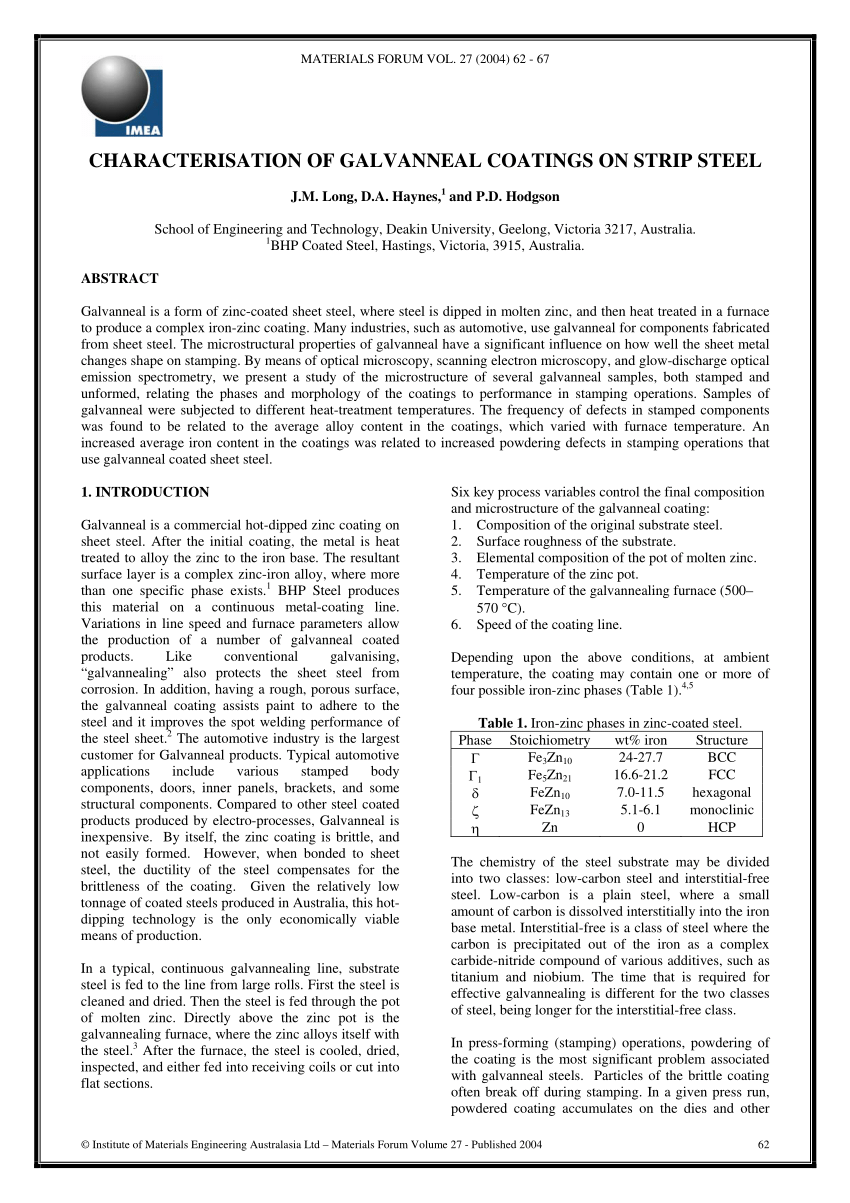

This is preferred over galvanized if the metal is to be painted. In comparison to galvanized steel the coating is harder and more brittle. Hot rolled galvannealed steel is derived from the temperature of the alloy when it is rolled into a sheet. The hot dip process pioneered by ak steel provides a tight metallurgical bond between the steel and coating.

Can be painted in the as shipped condition. Galvannealed steel has very similar properties as standard galvanized but the surface has a more porous and abrasive finish that more readily accepts paint. Galvanneal is similar to other galvanized steels. Light grey matte finish.

In order to create galvanneal steel the material is run through a liquid bath of zinc alloy. Design must allow for some strength reduction near welds. Both are passed through a hot dip coating process. Galvannealed steel hot dip zinc iron coated structural steel annealed with guaranteed minimum yield strength.

It is perhaps most similar to hot dip galvanizing. They both are zinc coated at the mill and are designed for rust and corrosion resistance. May have minor scratching. Hot rolled steel is steel that has been heated above its recrystalization point and is pushed between two rollers to meet a certain length and thickness.

Galvannealed or galvanneal galvannealed steel is the result from the processes of galvanizing followed by annealing of sheet steel. Meets astm a653 09 specifications requirements. This zinc adheres to the surface without any large changes to the metallurgical properties of either the zinc layer or the steel. Best use is for painted applications.

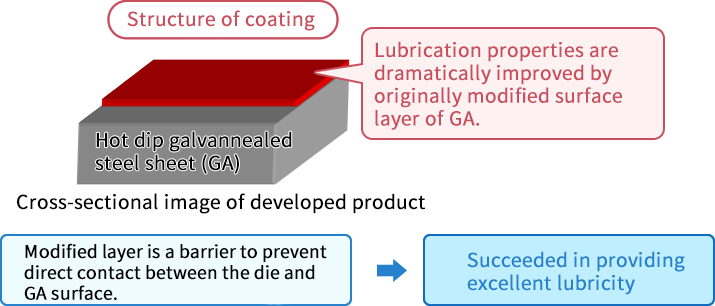

Has no protective film. The iron diffuses from the steel into the coating the galvannealed surface has a non spangled matte finish a finish very different than the highly metallic appearance of the galvanized coating. Galvannealed steel grade data sheet galvannealed steel hot dip zinc iron coated structural steel annealed with guaranteed minimum yield strength. Galvannealed steel is a specialized variation of galvanized steel where induction heating is used to alloy the zinc coating with the steel to create a zinc iron coating.

However galvannealed steel goes through an additional annealing process which induces diffusion alloying between the molten zinc coating and the steel. Galvannealed steel grade data sheet.